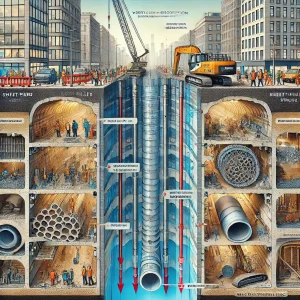

Urban infrastructure projects, such as installing sewer pipes, often face significant challenges, especially when traditional open trench excavation methods are employed in high-traffic areas. These methods can cause severe disruptions, affecting traffic flow, local businesses, and overall public convenience, which leads to increased project costs and public dissatisfaction. To address these issues, trenchless technologies like pipe jacking through microtunneling are frequently used. Microtunneling minimizes surface disruption by employing a remotely controlled machine that simultaneously excavates and installs pipes underground, making it highly suitable for densely populated urban environments.

However, despite the benefits of microtunneling, constructing the necessary launch and reception shafts introduces critical geotechnical challenges. Proper support of these shafts is essential to maintaining the stability of the excavation and ensuring safety during construction. A key debate among engineers is the effectiveness of different bracing configurations, particularly the use of single versus double-stacked bracing levels. This post explores these challenges and the effective use of GEO5 Sheeting Design and GEO5 Sheeting Check software, incorporating expert insights on optimal bracing strategies.

Case Study: Urban Sewerage Project

A relevant example is the “Establishment of Sewerage System” project, led by Power Construction Corporation. This project uses microtunneling due to the impracticality of open trench methods in the busy metropolitan environment.

In this project, the construction of launch and reception shafts required robust retaining structures to ensure excavation stability. During discussions, experienced engineers highlighted the potential pitfalls of using double-stacked bracing levels. They noted that double-stacking can lead to unequal force distribution between the levels, with the lower member often bearing a disproportionate load, which compromises structural performance. Instead, experts recommended using single-member walers, brackets, and other strategic bracing methods to achieve better load distribution and reduce the risk of bracing failure.

GEO5 Sheeting Design: Geotechnical Methods and Applications

GEO5 Sheeting Design is a robust tool for designing retaining structures such as sheet piles, diaphragm walls, and other sheeting types used in deep excavations. It incorporates several advanced geotechnical methods tailored to urban excavation challenges:

- Limit Equilibrium Method (LEM): This primary analysis method evaluates the stability of retaining structures by assessing forces acting on the wall, including active and passive earth pressures, surcharge loads, and groundwater forces. By calculating the equilibrium of forces and moments, the software determines the required dimensions and embedment depths for stability.

- Soil-Structure Interaction Modeling: The software uses detailed models that incorporate soil parameters such as cohesion, internal friction angle, unit weight, and modulus of elasticity. This allows for realistic simulations of the interaction between retaining walls and surrounding soils under various loading conditions.

- Bracing and Anchoring Analysis: GEO5 Sheeting Design evaluates the impact of internal bracing systems like walers and struts and external anchoring solutions like tiebacks. The software calculates forces on these elements, ensuring they are designed to handle expected loads without excessive deformation or failure.

- Water Pressure Consideration: The software considers hydrostatic and seepage forces on the retaining structure, crucial in areas with high groundwater levels. It allows for assessing the effects of dewatering and the design of appropriate water control measures.

- Stage Construction Analysis: Sheeting Design supports multi-stage construction analysis, enabling engineers to simulate the excavation process step-by-step. This feature helps predict the structural behavior as excavation depth increases, which is critical for maintaining stability.

- Deflection and Stability Checks: The program performs detailed checks on deflections and overall stability, calculating bending moments, shear forces, and displacements to ensure the structural integrity meets safety standards.

GEO5 Sheeting Check: Ensuring Stability Through Verification

GEO5 Sheeting Check serves as a verification tool, confirming the safety and stability of designed retaining structures. It employs advanced analytical methods to validate design performance under real-world conditions:

- Verification Using LEM and FEM: Sheeting Check uses the Limit Equilibrium Method (LEM) and Finite Element Method (FEM). The FEM in Sheeting Check specifically utilizes the Pressure Dependent Method, which accurately captures soil behavior under different pressure conditions, providing a realistic representation of soil-structure interaction.

- Pressure Dependent Method in FEM: This method models loads on the retaining structure based on its deformation, allowing engineers to simulate construction processes realistically. It provides a detailed analysis of the internal forces and displacements, particularly during staged excavations.

- Detailed Load Distribution Analysis: Sheeting Check evaluates the distribution of loads on all components of the support system, including sheet piles, walers, struts, and anchors, ensuring balanced forces to prevent structural failure.

- Compliance with Standards: The software checks the design against relevant standards, such as Eurocode or AASHTO, ensuring that the retaining structures meet all safety and regulatory requirements.

- Structural and Soil Capacity Verification: Sheeting Check verifies both the structural capacity of retaining elements (e.g., bending resistance) and the soil’s bearing capacity, confirming that all components perform safely under operational loads.

- Serviceability and Deformation Checks: The program assesses deformations of the retaining structure, ensuring that movements remain within acceptable limits to avoid damage to adjacent infrastructure.

- Iterative Design Verification: Engineers can use Sheeting Check to adjust and refine their designs iteratively, ensuring all safety and performance criteria are met before implementation.

Expert Insights on Bracing Configurations: Avoid Double-Stacked Levels

In projects like the sewerage system, the choice of bracing configuration significantly impacts the stability and safety of excavation works. Experts have advised against using double-stacked bracing levels due to their tendency to create unequal load distribution, leading to increased stress on the lower stack. Instead, a single large beam, walers, and brackets should be employed for more uniform force distribution. This strategy not only improves structural performance but also simplifies field implementation, reducing the likelihood of construction errors.

Engineers can use GEO5 Sheeting Design and GEO5 Sheeting Check to model these scenarios and validate the proposed support systems. These tools enable precise simulations of different bracing configurations, providing valuable insights that align with expert recommendations.

Conclusion: Leveraging GEO5 for Safer and More Efficient Urban Excavations

The use of GEO5 Sheeting Design and Sheeting Check offers invaluable support in the design and verification of retaining structures in urban excavation projects. By employing advanced geotechnical methods, including Limit Equilibrium and Finite Element Analysis with the Pressure Dependent Method, these programs provide a comprehensive understanding of soil-structure interaction. Incorporating expert insights on optimal bracing configurations further enhances the reliability of designs, ensuring safe, efficient, and compliant construction practices.

To explore how GEO5 software can optimize your geotechnical projects, try our free trials and book a free online presentation to see these powerful tools in action. Ensure your designs stand up to the challenges of urban excavation with GEO5.